Marktech Optoelectronics

3 Northway Lane North

Latham, NY 12110

Fax: +1-785-4725

Email: info@marktechopto.com

The broadest line of both silicon and InGaAs detectors commercially available.

Indium Gallium Arsenide (InGaAs) PIN photodiodes are made using InGaAs/InP technology.

Cutting-edge silicon photodetectors that excel in precise detection of light ranging in wavelength from 250nm to 1100nm

Monolithic “quads” or quadrant photodiodes (QPDs) are 2 X 2 photodiode arrays with four planar diffused photodiode elements or segments.

Marktech offers a broad line of silicon photo Transistors in a variety of package types ranging from miniature metal can to ceramic packages.

Our High-Reliability Photoreflectors are sensors that contain both the LED emitter and photodetector functions within a single package.

Marktech Si APD’s offer low-level light and short pulse detections of wavelengths between 400 nm and 1100 nm.

UV detectors are offered in a variety of TO metal-can type packages from TO-18 to TO-39 with special UV glass lens to insure optimum lifetime and the least amount of material degradation

With the ability to detect light in the UV, visible, and infrared spectrums, photo detectors, photo transistors, and photodiodes are being used in increasingly more applications.

Marktech offers the broadest range of emitters commercially available ranging from 235nm to 4300nm across the UV, visible, NIR, SWIR, and MWIR spectral ranges.

Marktech offers the broadest range of UV LEDs commercially available ranging from 235nm to 400nm including UVA, UVB, UVC, and deep UVC LEDs.

Our advanced line of visible LED products is engineered to deliver high-quality, energy-efficient lighting solutions across various applications from 400nm to 700nm..

Our NIR LED wavelength range is typically from 700nm to 1000nm, extending into wavelengths invisible to the human eye but crucial for numerous technological and scientific applications.

Our standard product offering includes wavelengths from 1020nm to 3000nm and operating currents ranging from 20mA to 350mA for high-power applications.

Our Point Source LEDs are specifically engineered for optical encoders, edge sensors, and other critical applications that demand highly focused light with minimal dispersion.

Multi-LED chips in a single package, our multiple wavelength LEDs are engineered to address a myriad of applications across the UV, visible, NIR, SWIR, and MWIR spectral ranges

Designed to produce a highly defined red dot or reticle, facilitating accurate aiming without revealing the location to the target.

Ideally suited for applications including edge sensing, line sensing, coin bill validation, and bar code reading

Our panels are crafted to deliver uniform, vibrant illumination across a wide range of applications, from consumer electronics to industrial displays.

Crafted with the latest LED technology, these rings provide adjustable illumination to meet specific needs, ensuring optimal visibility and enhancing the quality of your projects.

As a proud CREE LED Solution Provider for over a decade, Marktech offers comprehensive engineering support, including design, binning, and material selection, alongside custom packaging options for specialized applications.

CREE LED through-hole emitters, designed for high-temperature and moisture environments with UV-resistant optical-grade epoxy, offer a range of colors for versatile applications in signage and lighting.

CREE High Brightness (HB) SMD LEDs are the brightest, most reliable architectural, video, signage, scoreboard, roadway, and specialty LEDs available today.

CREE LED’s P4 series represents a leap in LED design, combining efficiency with aesthetic versatility to meet the demands of modern lighting applications.

Marktech’s CREE LED XLamp® offerings on aluminum core starboards simplify LED integration for designers, providing a range of colors and angles on compact boards for easy testing and implementation in varied lighting applications.

Marktech Optoelectronics introduces its new product line of CREE LED die, including the EZ1350 Series Die, packaged in TO-cans (TO-18 and TO-39 outlines) designed for precision and reliability in demanding applications with protection against environmental factors like moisture and dust.

Marktech Optoelectronics combines over 40 years of expertise in optoelectronics with a focus on customized engineering solutions, addressing specific customer needs and applications.

Custom photodiode detectors are designed to meet unique customer requirements, offering specialized performance features and cost savings through optimizations such as integrated filters, photodiode arrays, and hybridization.

Through our vertically integrated manufacturing facilities in California and Japan, we offer custom LED solutions, including packaging and optoelectrical categorization, enhancing product design and market readiness.

Multiple LED dies combined in a single package are engineered to address various applications across the UV, visible, NIR, SWIR, and MWIR spectral ranges.

To succeed, you need the exact optoelectronic package custom-designed and manufactured for your application, including hermetic metal SMD, TO-can, plastic SMD, and molded through-hole packaging.

Made-to-order semiconductor chips (die) and wafers are designed and fabricated to fit your needs. Standard dies are available in specific wavelengths for high-volume production applications.

Bare and encapsulated LEDs, photodiodes, and other components are assembled on FR4, metal-cored, and flexible circuit boards, ready for production.

Learn about the latest trends, devices, and potential applications.

The latest news and announcements from Marktech Optoelectronics.

Detailed information about common uses for Marktech Optoelectronics devices.

In depth discussions on LEDs, Detectors and the science behind them.

Become familiar with common terminology and concepts for LED Devices.

List of common concepts and definitions for Photodiodes.

LEDs (Light Emitting Diodes), semiconductor light sources, have been introduced and developed for several decades. LEDs are applied in many devices as indicators and general illumination products such as lighting components. As a “green” light source, LEDs can provide long life time and high efficiency light for many applications. However, for some special applications, standard LEDs are not always the perfect choice. Point Source Emitters (PSEs) offer a great alternative in applications needing a precise beam of light such as encoders, machine vision and medical fiber.

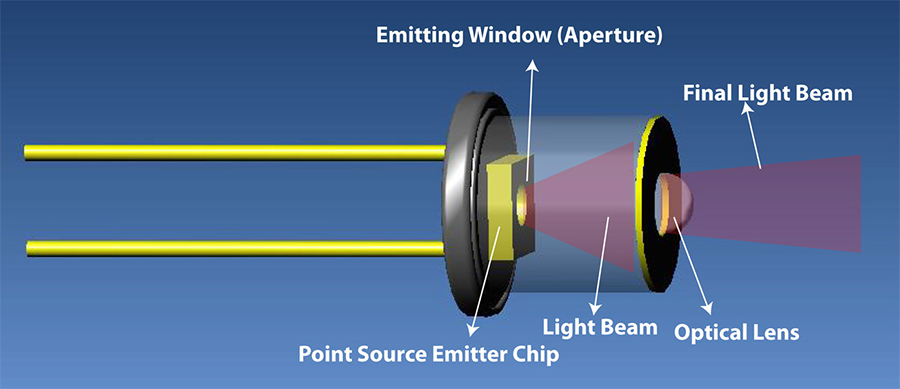

Point Source Emitter is a semiconductor diode similar in structure to a standard LED, however, the light is emitted through a well defined circular area, typically 25μm-150μm in diameter. The light produced appears as a “spot”. The output light produces very narrow, almost parallel viewing angles. These two characteristics are well suited for applications which require a near parallel light source and lower power, as compared with laser diodes.

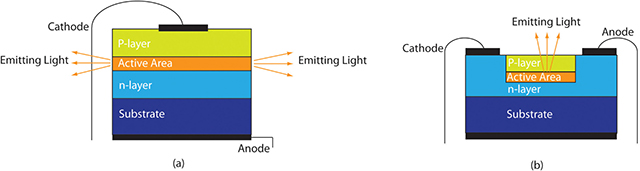

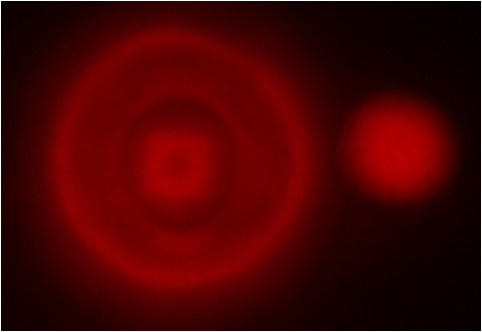

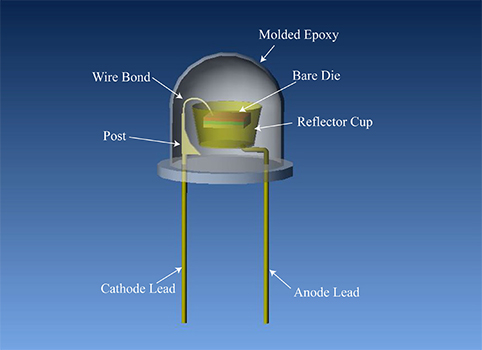

Figure 1 shows side view structure of standard LED and PSE. First, the difference in these two structures is emitting light direction. Standard LED output light is directed to the side. In order to refocus the light direction, standard LEDs normally need a reflective cavity to force the light from side to top. This can cause light output loss, power dissipation, and variations in final output light beam and viewing angle. However, PSEs emit light to the upper surface though an aperture / window on top of the structure. Second, the difference in these two structures is the position of the cathode contact. The cathode contact pad of a standard LED is typically located in the center of the structure, which can obstruct light output due to the top wire bond. Point source emitters can easily solve this problem by locating the cathode contact wire bond to the side of the aperture window, eliminating any obstructions and dark spots (represented in figure 2). The light emitted from the standard LED (left in figure 2) has several dark spots due to the bonding pad, obstruction from the wire bond as well as the reflector cup (shown in figure 3). Point source emitter (right in figure 2) has a much more narrow, defined, and precise beam with no dark spots.

Figure 1, Side View Structure of Standard LED and Point Source Emitter. a). Standard LED Structure (b). Marktech Point Source Emitter Structure

Figure 2, Lighting Comparison of Standard LED and Point Source Emitter. Left is standard LED light ouput, and right is point source emitter.

Figure 3, Schematic of Standard LED.

Aperture size, a key parameter of PSEs, can affect power output. A smaller aperture will typically result in a lower power output, however, it will also increase the resolution capability. Point source emitters are offered in a variety of wavelengths and aperture sizes to satisfy individual application requirements. Currently, PSEs are available in wavelengths from red light (650nm) to infrared (IR) light (880nm). More details are presented in Table 1.

| Emitting Light Color | Wavelength | Aperture Window Size |

|---|---|---|

| Red | 650nm | 25μm |

| Red | 650nm | 80μm |

| Red | 650nm | 150μm |

| Infrared (IR) | 850nm | 50μm |

| Infrared (IR) | 850nm | 150μm |

| Infrared (IR) | 880nm (Under Development) | 50μm |

| Infrared (IR) | 880nm (Under Development) | 150μm |

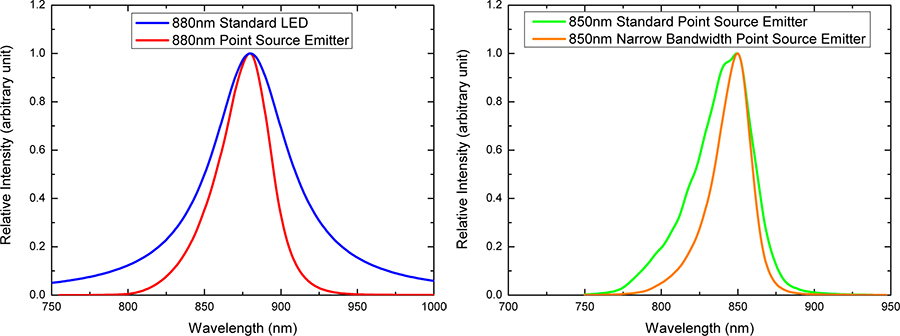

Standard LED emitting light is neither monochromatic like a laser nor broadband like a tungsten lamp, but rather lies in between these two. Hence, output light bandwidth is another significant consideration for different applications. In general, the spectrum bandwidth of LEDs is in 30nm to 100nm range, where PSEs offer a much narrower 20nm—50nm bandwidth. However, some special applications need an even narrower bandwidth. For example, the image system in some microscopy applications require narrow band emissions from the emitter as well as less stray light in the background of the image of the test sample.

Figure 4 shows the spectrum of 880nm standard LED and 880nm PSE. Blue line in this figure represents 880nm standard LED spectrum with 60nm bandwidth; red line stands for spectrum of 880nm PSE. The typical bandwidth of 880nm PSE is 40nm, 20nm less than standard LEDs. This demonstrates that PSEs emit a much tighter monochromatic beam compared to LEDs.

Figure 5 shows the spectrum of 850nm standard and narrow bandwidth PSEs. Green line in this figure is 850nm standard PSE spectrum with 40nm bandwidth; orange line symbolizes spectrum of 850nm PSE with narrow bandwidth. The typical bandwidth of 850nm narrow bandwidth PSEs can reach 25nm; even lower depending on the customer’s requirement.

Characteristically, the luminous intensity of LEDs gradually decreases over the life of the LED. The rate at which the luminous intensity falls varies according to the material used and the forward current at which the LED is driven. The larger the current, the greater the diminution of luminosity. Thus, when setting the forward current of the LED lamp, do not determine the setting solely from the temperature characteristics, as in the above example, but consider also longevity characteristics. An effective way of improving the longevity characteristics is to set the forward current of the LED lamp relatively low.

LED viewing angle is primarily a function of chip type, package and optics. Standard LEDs have a viewing angle of 15°-120°. Point source emitters can be offered with narrow viewing angles as narrow as 40 using special optics. There are several technologies that may be utilized to optimize viewing angle including using an external optical glass lens or internal ball lens. These lenses can not only

reduce light loss and optimize the light trace, but also can enhance product reliability. Standard LEDs are typically encased in an epoxy or plastic materials. Some of these encapsulants can chemically react with the die causing premature light output degradation. Many PSEs are packaged in hermetically sealed housings with either air or nitrogen inside. This can significantly improve the life time and output degradation of the PSE. Figure 6 shows an example of an external glass optical lens being applied.

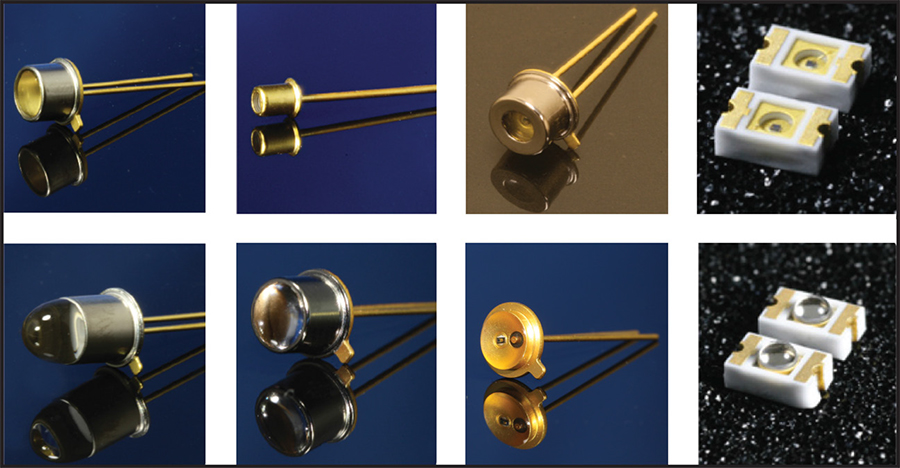

A variety of high reliability package options, including hermetically sealed TO-18 and TO-46 metal cans, coaxial metal can and ceramic surface mount packages can be obtained. All these packages can have varying package heights and lens options, providing the designer with optimum flexibility in sophisticated design efforts. Lens options includes flat glass window, dome lens, etc. Figure 7 shows some standard PSE package styles. Custom package solutions are also available.

Characteristically, the luminous intensity of LEDs gradually decreases over the life of the LED. The rate at which the luminous intensity falls varies according to the material used and the forward current at which the LED is driven. The larger the current, the greater the diminution of luminosity. Thus, when setting the forward current of the LED lamp, do not determine the setting solely from the temperature characteristics, as in the above example, but consider also longevity characteristics. An effective way of improving the longevity characteristics is to set the forward current of the LED lamp relatively low.

Marktech Optoelectronics

3 Northway Lane North

Latham, NY 12110

Fax: +1-785-4725

Email: info@marktechopto.com